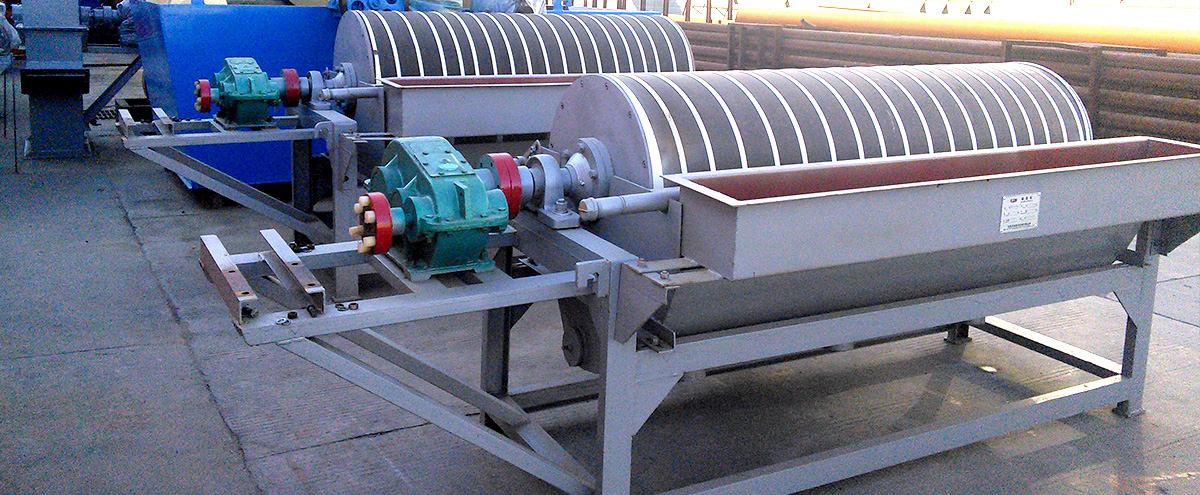

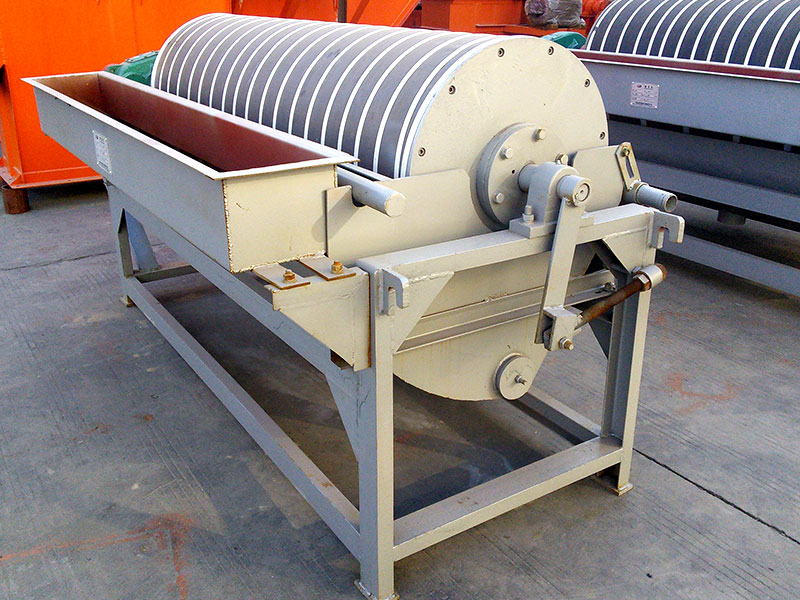

FTM magnetic separator is an important equipment in magnetic separation, it usually used for ore dressing of various kinds of hematite, pyrite and other magnetic minerals. During the work of magnetic drum separator, the strong magnetism of the magnetic separator is used to separate and recycle the ore and non-magnetic materials. The magnet separator manufactured by FTM has unique magnetic field distribution(MFD), both large and small particles can get maximum recycling, at the same time its separation part designed with reasonable structure of pulp flow, plus good wear-resisting magnets, so that the mineral recovery of magnetic separator is huge, saving the energy consumption at the same time.The permanent magnetic drum separator can be equipped with three kinds of discharge through, which can be fully matched with the user's demand.The permanent magnet system is composed of a new composite ferrite and composite steel material. The surface strength of the system can reach up to 600mt.

Wide application range and flexible configuration;In addition to the magnetic mineral separation, it can also be used for the selection of iron in the river sand and ceramics.

Long service life and low maintenance cost; The tank of the magnetic separator is treated with glue, which reduces corrosion and wears, and the surface magnetic substance of the drum is easily replaced.

Strong magnetic field and processing power;The magnetic substance is made of composite material, which has high magnetic induction intensity, large magnetic field depth, little material jam, and strong continuous production capacity.

Promoting the recycling of resources and sustainable development;We produce the wet-type permanent magnetic drum separator to improve the low-quality minerals, reduce the burden of the next process, and make the maximum recovery of the resources.

At work, the drum of the magnetic separator spins and the magnetic system does not move. The fine grinding pulp is sent to the sorting trough passing through the ore box, the magnetic particles are magnetized under the action of the non-uniform magnetic field, which is attracted to the surface of the drum by magnetic field and rotating the drum. Magnetic particles are transported to the magnetic field outlet, because of the magnetic weakening and the scour of water, they are expelled as concentrates from magnetic attraction finally. Non-magnetic minerals are left to tailings in the pulp as they are not attracted to the magnetic field.