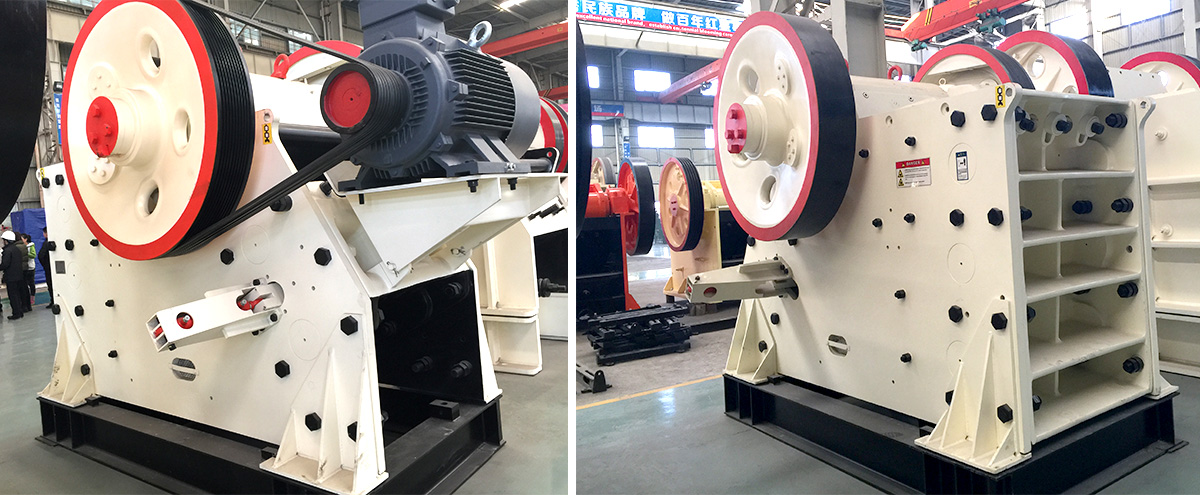

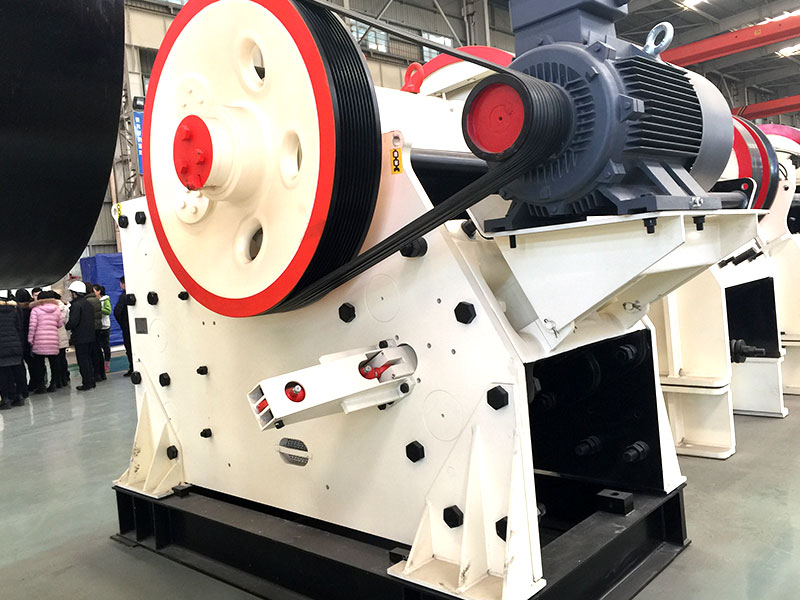

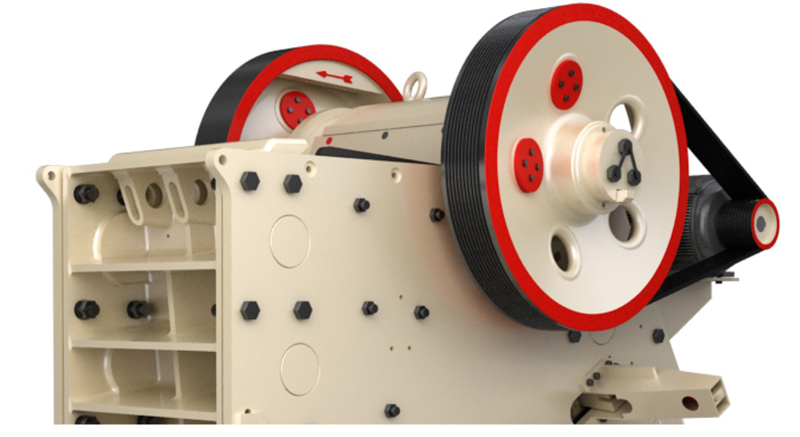

FTM CJ series jaw crushers is a high-performance jaw crusher introduced and developed by Henan FTM Heavy Machinery Co., Ltd based on customer and market demand. Different from the traditional jaw crusher, this series of jaw crusher has been improved at movement parameters, structural form and adjust method. CJ series jaw crusher has advantages of less land occupation, big crushing ratio, and smooth operation, easy to install, maintain and adjust. It is particularly suitable for fixed crushing plant and mobile crushing plant. and the cj jaw crusher with the technical features of bolted and disassemble frame, optimized movement parameters , enhanced bearing design, wedge block discharge adjustment, steel plate made toggle plate, integrated motor seat and Integrated steel base.

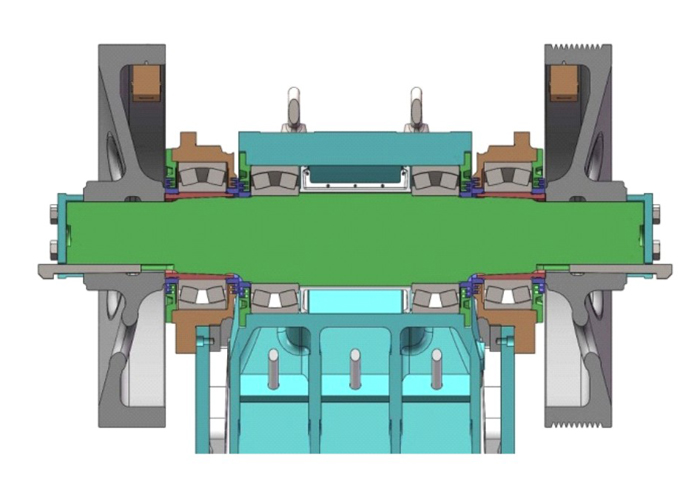

Stronger and more reliable structure, easy to transport and install, especially convenient when working underground.The front plate, side plate and rare frame are connected by cylinder pins and fastened by bolts, which makes it a stronger and more reliable structure, also this type of structure has avoided the accumulation of inner stress which always happen to a welded jaw crusher frame. This disassembles frame is easy to transport and install, especially convenient when working underground.

Bigger stroke and higher crushing ratio; The optimized movement parameters make the crushing take place when rock enters at the upper part of the crusher chamber; while at the lower part of the crusher chamber, it has a bigger stroke and higher crushing ratio.

Longer service life, fewer spare parts number; Longer service life has been guaranteed by adopting bigger bearings; in the mean time, the toggle bearings and frame bearings are with the same model which reduces spare parts number.

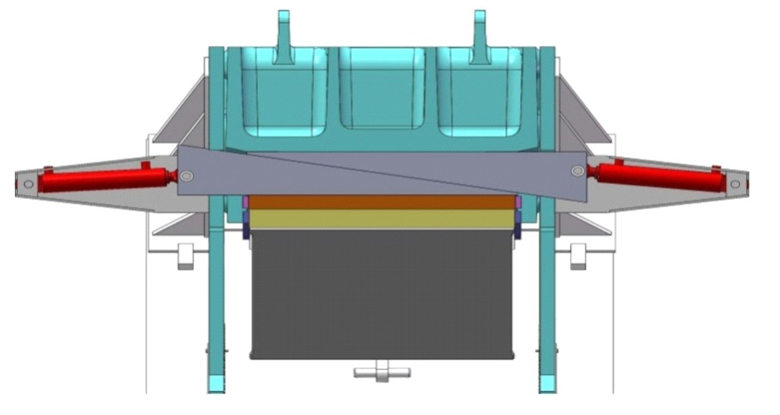

Fewer labor force and down time compared to the traditional one; Wedge block discharge adjustment reduces labor force and down time compared to the traditional spacer plate adjustment method. Hydraulic cylinders can be installed which makes the easier adjustment.

Better to protect crusher body and belt conveyor; The newly designed toggle plate is made from high strength steel plate; it protects the crusher body when the crusher is overload. This light-weight toggle plate is easier to be replaced compared to the traditional heavy-weight casted toggle plate; moreover, this light-weight toggle plate does not damage the belt conveyor when it drops.

Easy installation, less used field area; The integrated motor seat design makes easier install and takes less land.

Little effect on a foundation; The crusher is seating on the steel base, while vibration absorbers have been applied between them in order to reduce the vibration to the foundation.