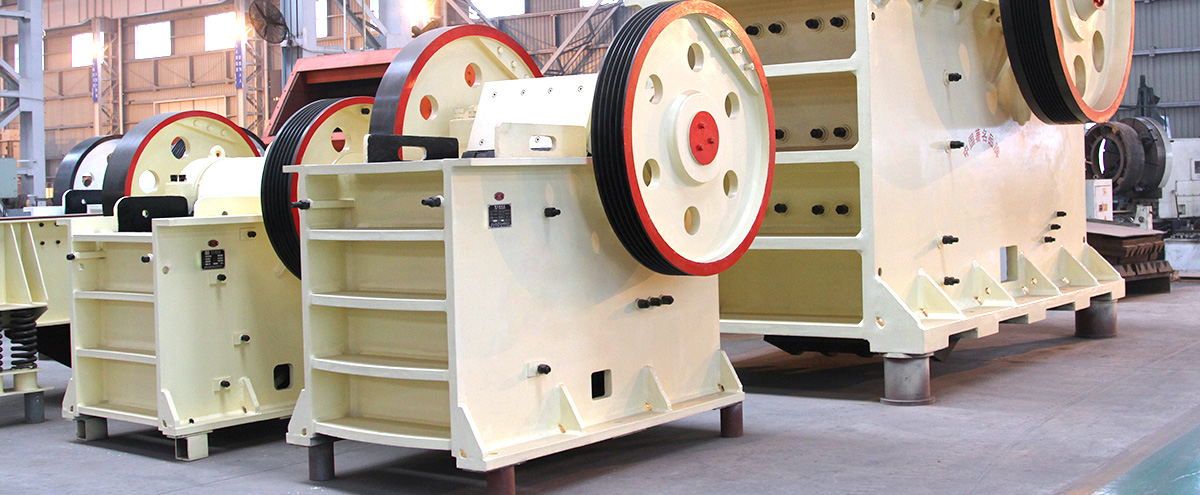

As the first choice of coarse broken ,PE jaw crusher with advantages of Cost-effective,low requested for materials size and low investment cost is the most familiar primary crusher for us in mining and construction industry, as we all know, jaw crushing machine can break these materials: ore, rocks, granite, marble, construction waste, concrete, river stone, etc into needing size for the next step of processing.

In the long run R & D of the machine and comm unication with customers, our company also produce PEX series of fine jaw crushing machine to meet the part of the customer's requirements for finer material granularity.It enjoys the advantages of cheapest secondary crushing equipment, Large output, High intensity, Convenient to repair and so on.

How to adjust discharge port of PEX series of fine jaw crusher machine? When you need to reduce the discharge port of PEX Jaw Crushers, first loosening the nuts No.1,2,4, then use the wrench to stop screw No.3, making stop screw forward to lift adjusting bearer, inserting new gasket into gasket group, until reaching to the required discharge opening size, first returning stop screw 3 (remembering stop screw can not be forced when Jaw crusher machine working normally), tightening the nut No.2 to compress gasket group, and then tighten the nut No.1 and fix adjusting bearer, finally tightening properly the pull-rod spring No.4. On the contrary, the discharge port can be changed from being minor to being major ( pulling out the gasket).