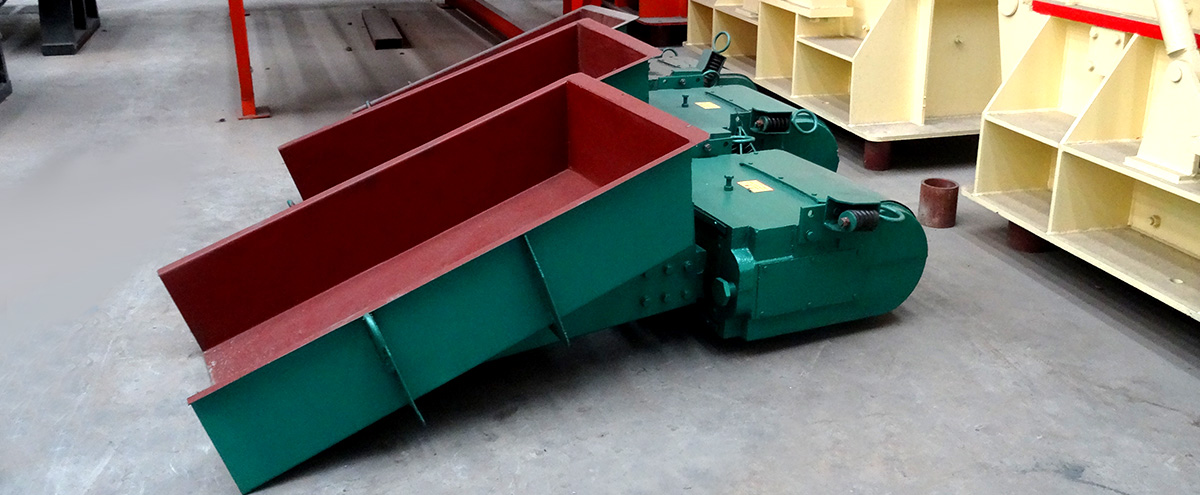

FTM electric magnetic vibrating feeder is widely used in mining, metallurgy, coal, building materials, light industry, chemical industry, electric power, machinery and other industries. It is used for uniformly, continuously or quantitatively feeding the block, granule and powdery material from a storage bin or a funnel to a receiving device

Simple structure and convenient maintenance; The whole machine has no rotating parts and no lubrication needing, the feed trough of this vibrating feeder is made of alloy steel plate with long service life.

Uniform feeding and less wear in parts; Using the principle of electromagnetic vibration and the amplitude is stable. The material is continuously thrown in the feeding process, and the contact with the feeding trough is less, so the wear of the feeding trough is smaller.

Automatic control system and saving energy; The instantaneous change and opening of the material flow, the accurate material, adopt the principle of resonance, the mass work in the low critical resonance state, and thus consume less power.Instantaneous change and opening of the material flow, accurate feeding and the use of resonance principle, which make double-body working in the low critical state of resonance with less electric consumption.

Wide applicable material and high production efficiency;It is suitable for conveying high temperature and corrosive materials, and the automation of production process improves production efficiency.

Important Note: This series of electric vibration machine is not suitable for situations where there are explosion-proof requirements!

The vibration source of vibrating feeder is electromagnetic vibration exciter, and the vibration exciter is made up of two eccentric shafts and gear. The motor drives the drive shaft through the triangle belt, then the upper gear of drive shaft rotates with the driven shaft, the drive shaft and driven shaft rotate reversely at the same time to make the trough vibrate, eventually, the continuous flow of materials reaches the purpose of conveying materials.